Industrial robotics /

automation use cases

Human-Robot-Interaction in Semi-Automated Assembly Processes

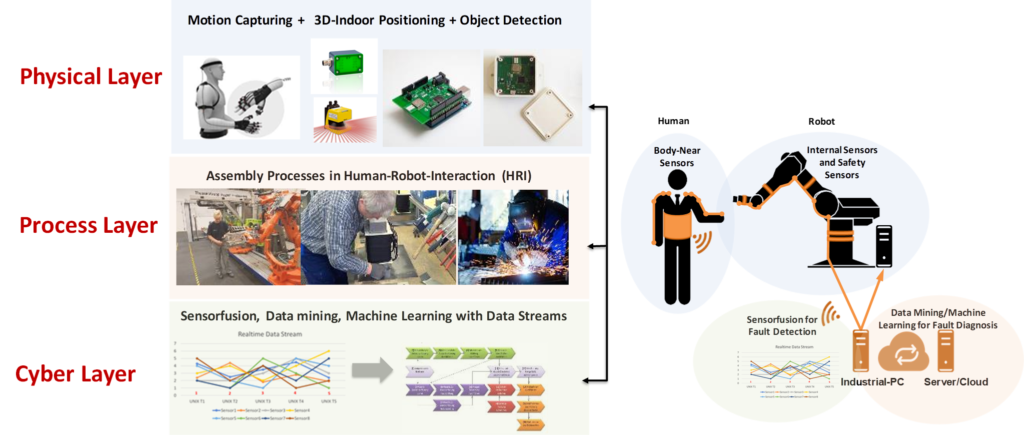

The use case takes place on the shop floor level, and focuses on real-time object tracking and detection in industrial IoT environments. It is based on a wearable motion tracking sensing system combined with a low-energy single-board computer for data preprocessing, sensor fusion and wireless transmission. The described system can be considered as the means for a wider spectrum of sophisticated security, safety and context-oriented applications in IoT environments, such as collision avoidance. The idea is to set up a real-time data stream processing pipeline to record external and internal sensor data of the HRI system. The aim of the use case scenario is to recognize and detect failures in the data stream which might lead to a malfunction of the collaborative robot and an injury of the human worker. This will form the basis to extract single data segments form the stream, and eventually to recognize faults within the data patterns. These sequential patterns will be labelled and stored in the cloud, while at the same time representing the main input for conducting machine learning techniques (classification or regression), typically Neural Networks or Support Vector Machines.

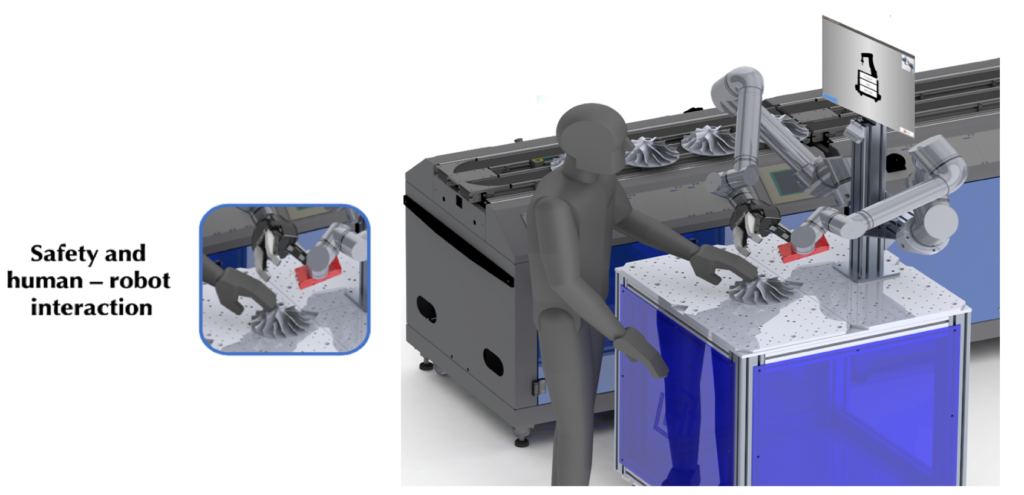

Human-Robot Collaboration in a disassembly process with workers with disabilities

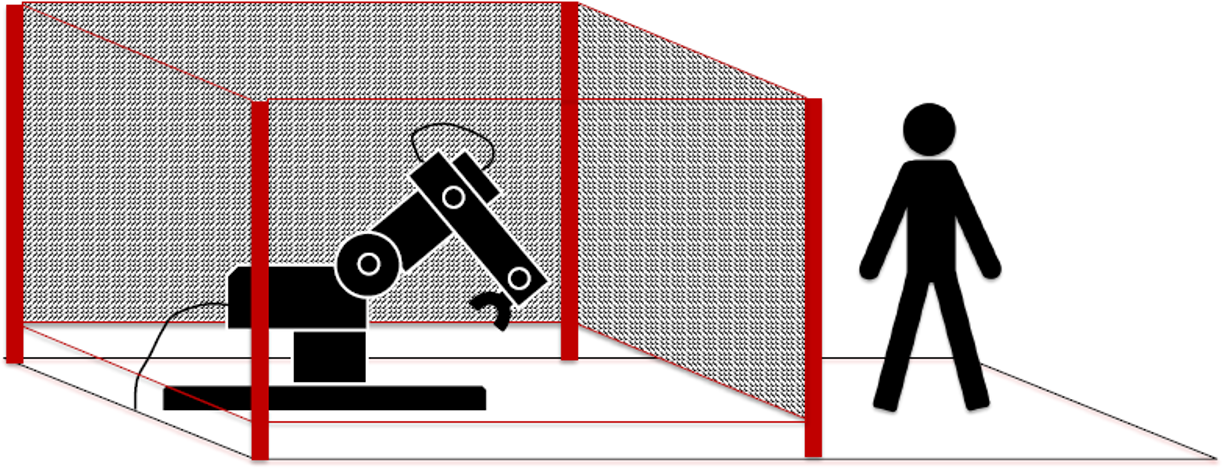

Currently, the EU Machinery Directive (U.S. OSHA (29 CFR 1910)) and other regulations oblige machine manufacturers to install safety measures to protect operators and other employees from danger. In collaborative robotics, the standard dictates the need to define four characteristics for a robot to be collaborative: (i) design the collaborative workspace; (ii) definition of the collaborative operation: minimum robotoperator separation, maximum speed, static and dynamic limits, ergonomics; (iii) methods for collaborative work: safety controlled stop, manual guidance, distance and speed control, etc.; and (iv) definition of the difference between collaborative / non-collaborative. The aim of the Fundaci´on Aspace Navarra para el Empleo (FANE) organisation is to satisfy the labour needs of disabled people in order to make easier their integration in the common labour market The VALU3S technology can facilitate the thorough V&V activities that will be required by regulators for this type of technology by providing a validated platform for the systematic testing of complex software systems. The objective of this use case is to use the VALU3S in a collaborative robotic application.

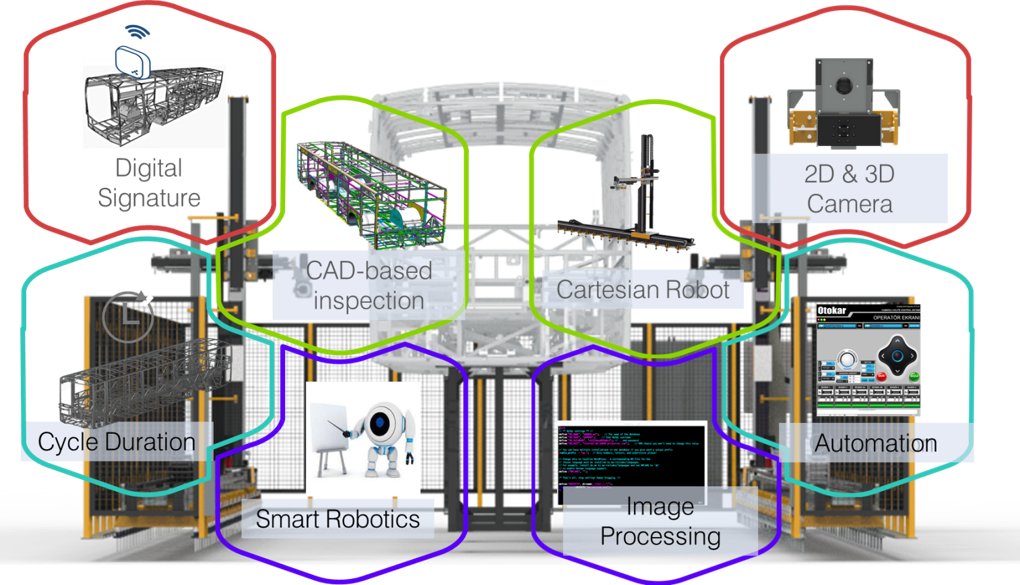

Automated robot inspection cell for quality control of automotive body-in-white

The goal of this use case is to provide a better fault-tolerant production line to achieve better quality control for automotive body-in-white. Quality control has been carried out by means of the camera system positioned on the cartesian robot located on both sides of the vehicle body (i.e bus). The data obtained from the CAD data of the large bodied vehicle is compared with the actual data obtained from the camera system by means of the synthetic data obtained from the developed data, and the item presence/absence check and critical measurement controls acquired from sensors and actuators. To ensure that VALU3S technology is applicable to the robot inspection cell for quality control, in this use case, we will cover an automated fault and attack injection, specifically for controlling the entire industrial automated line. The use case will be evaluated in the context of VALU3S considering security and safety, e.g. demonstrating results from simulations and the role of VALU3S in decision making, assessing full inspection processes in terms of task completion rate, duration and safety metric, considering time required to detect and overcome faults and attacks, and anomaly detection at component and system level by utilizing ML techniques.

Industrial Drives for Motion Control

The industrial drives for motion control use case focuses on a generic commercial motion control platform solution for permanent magnetic synchronous motors. The available system fo this case study was already designed in SESAMO & AQUAS ECSEL projects to comply to Safety Standard IEC 61508 and IEC 62443 from the security perspective. As a basis for VALU3S, one FPGA based hardware prototype along with a virtual prototype is available. VALU3S perfectly complements the previous work with respect to the focus on V&V. Especially the change towards the new processor architecture causes significant verification efforts of safety and security features where effective fault and attack injection can bring high value.